Slating Guide

For details on the process of slating, reference should be made to BS 5534: 2003 Codes of Practice for Slating and Tiling, but here’s a few pointers to ensure you achieve a satisfactory finished roof.

If the slate has been sorted and the roof marked out properly, then laying the slate is straight forward. However, the recent trend is to forklift a pallet on to the scaffold and lay the slates straight out of the pallet without grading. It is unlikely to achieve a satisfactory finish this way.

The proper grading and selection of slates is extremely important to achieve a neat and attractive finish. All slates must be sorted regardless of what grade they are. The best grade are more consistent, but will still have to be put into at least 3 separate thicknesses. Any twisted or broken slates should be set aside for cutting down for under-eaves, tops etc. Make sure sufficient room is available on site to enable sorting to be done.

The under-eave slate should be cut to the correct length, for example, a 500×250 slate laid to a 75mm headlap should be cut to 288mm long (gauge + lap). A common short cut is not to cut the full slate but to turn it around and lay it along its length, so that the under-eave will then be 250mm rather than 288mm. This method could cause problems. The under-eave should be laid ‘back to front’ – and although not critical – it gives a neater appearance and is a good indication of a well trained slater.

When laying slates, if they do not lay flat, sometimes it helps to crop off one corner or both corners where they sit on the batten. If that does not remedy the situation, do not lay it as it will not flatten out over the time. Either use that slate as a cut elsewhere, or don’t fix it at all. Wastage will be about 4 to 5% on best grade slates and up to double that on second grade slates.

Slates should not be walked on. Fixed slates may also get broken by other trades accessing the roof. We recommend slates should be replaced using a stainless steel slate hook of the appropriate size, not stuck down with adhesive as they will very likely fall out over time.

Slates should be cut with proper slating tools and not too small. The narrowest part at the head or tail should be no less than 50mm, to enable a proper fixing – or a slate and half must be used, which we can also supply.

View Our Slates

-

Cinero Brazilian Grey Graphite Slate View Details

Cinero Brazilian Grey Graphite Slate View Details -

Lovat Brazilian Grey-Green Slate View Details

Lovat Brazilian Grey-Green Slate View Details -

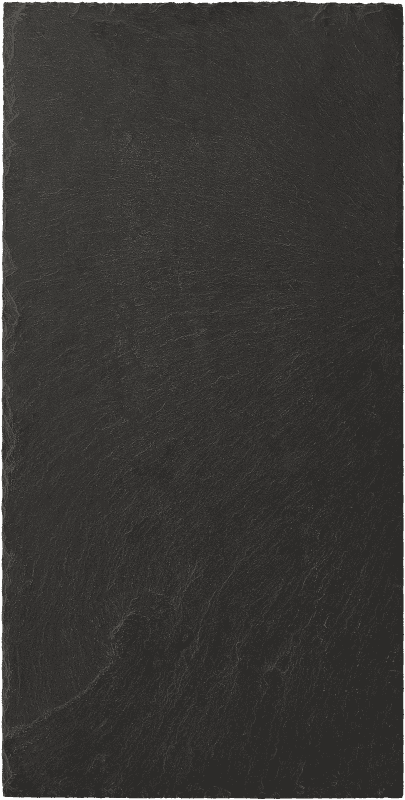

Mocha Spanish Black Slate View Details

Mocha Spanish Black Slate View Details -

Passaro Spanish Blue-Grey Slate View Details

Passaro Spanish Blue-Grey Slate View Details -

Liarn Spanish Grey Slate View Details

Liarn Spanish Grey Slate View Details -

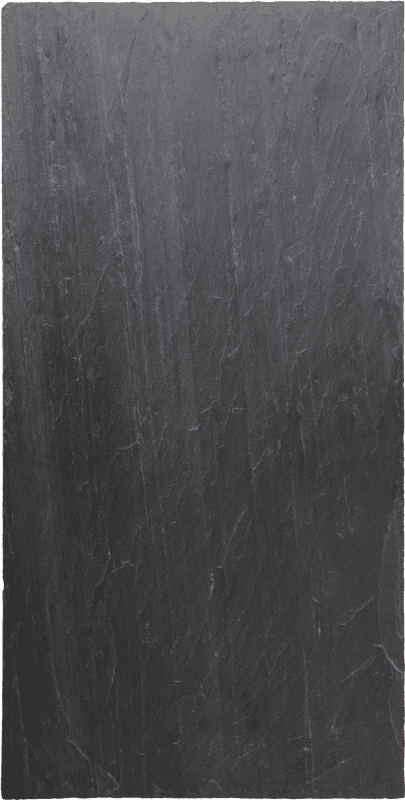

Melano Spanish Blue-Black Slate View Details

Melano Spanish Blue-Black Slate View Details -

Glendyne Canadian Grey Slate View Details

Glendyne Canadian Grey Slate View Details

Need help choosing a slate?

Our friendly staff are always happy to discuss your requirements or help you by answering any questions.